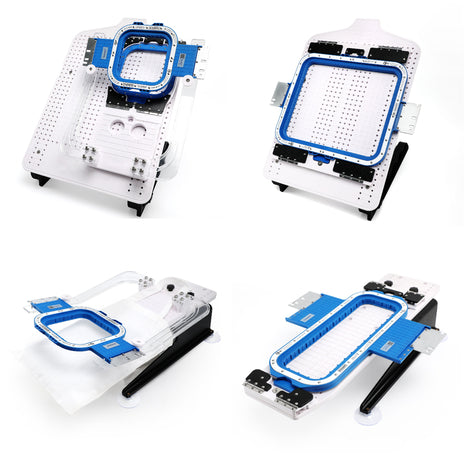

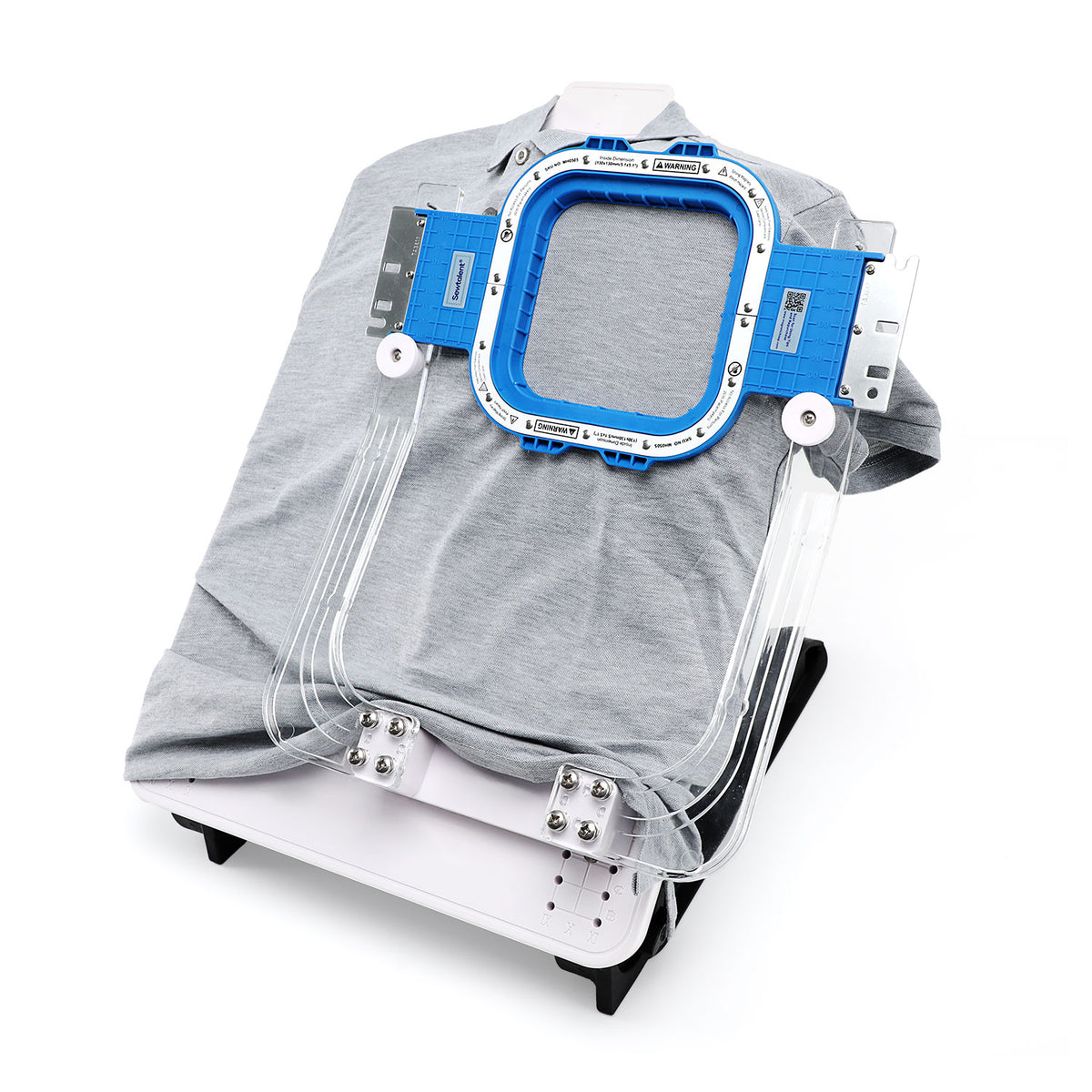

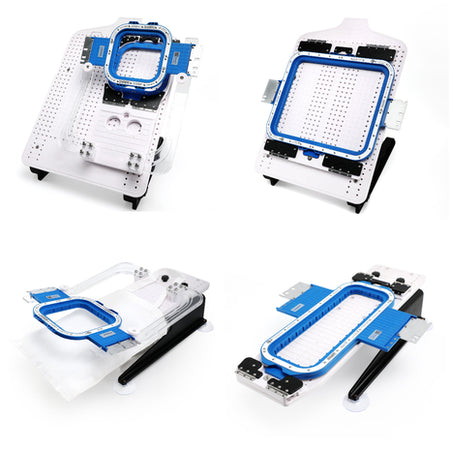

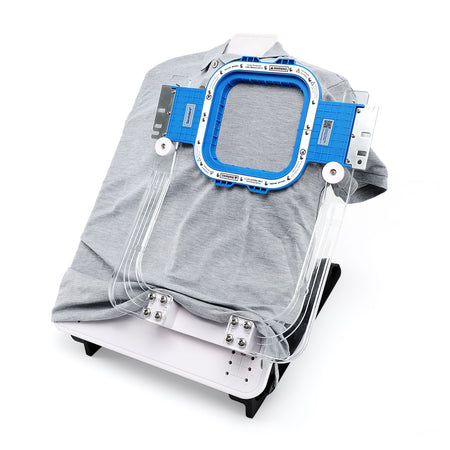

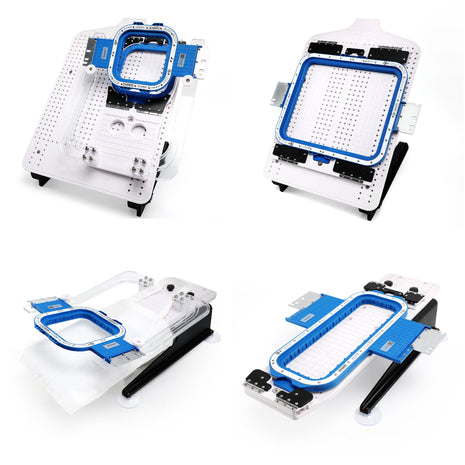

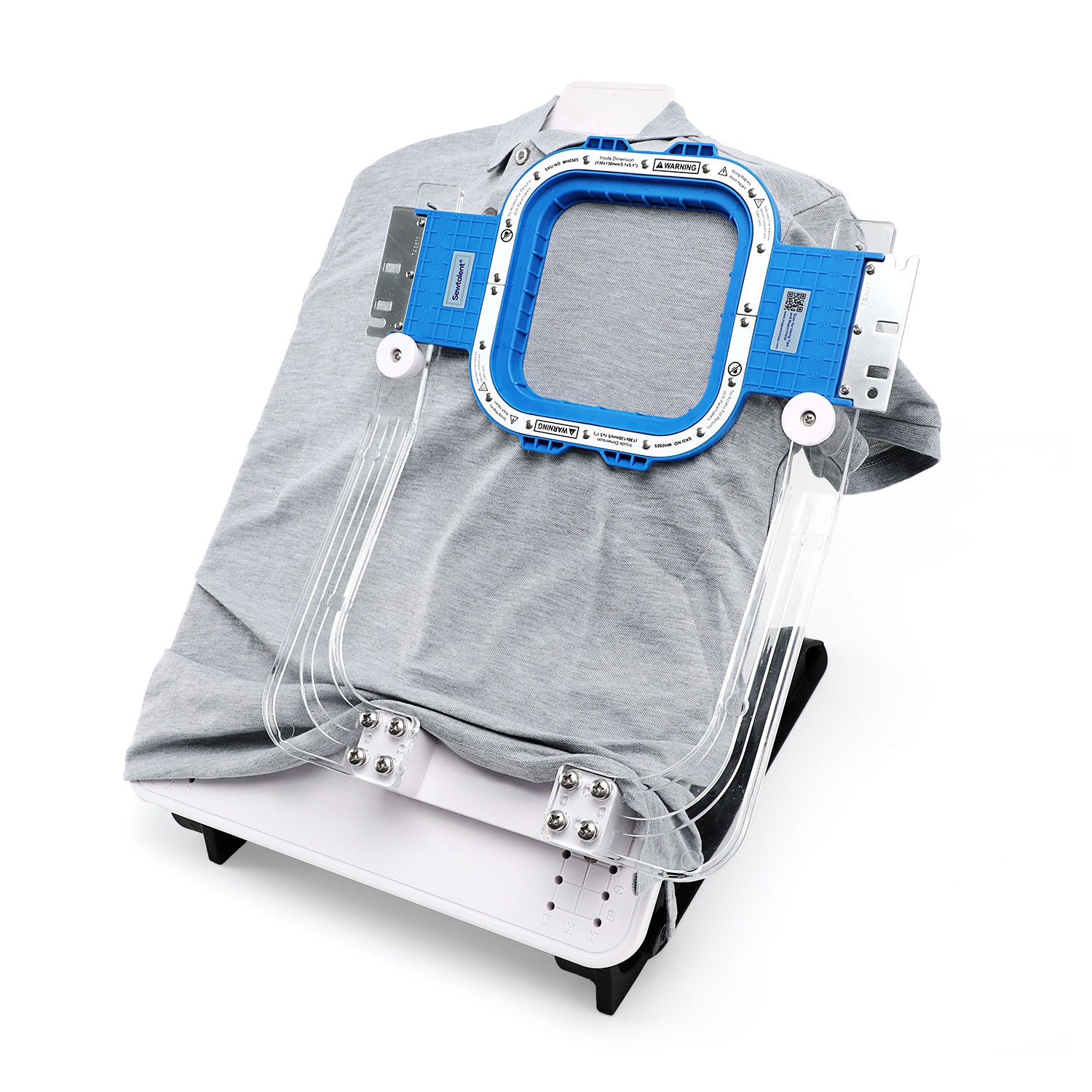

They were great@ They were able to get me on the right track. They were attentive and a great help! I am ready to start with my new hoops. I like the fact that they are somewhat freearm.

I'm really enjoyed my hoop.

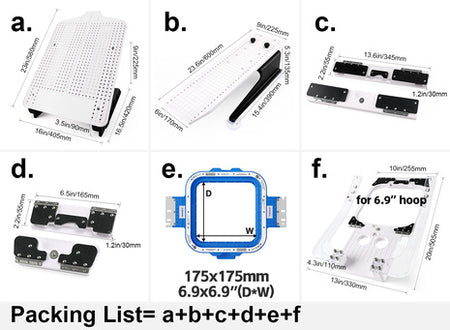

let me start by commending Olivia. She is amazing at her job and has great customer service. She took very good care of me. The Magnetic hoops and boards are fantastic. As good or better than the other brands and at a much cheaper price. You can't beat it. Quality is very good. They work great. I will continue to buy more. And I look forward to working with Olivia.

I have bought a magnetic hoop from this site, fast delivery, product good and wonderful assistance.