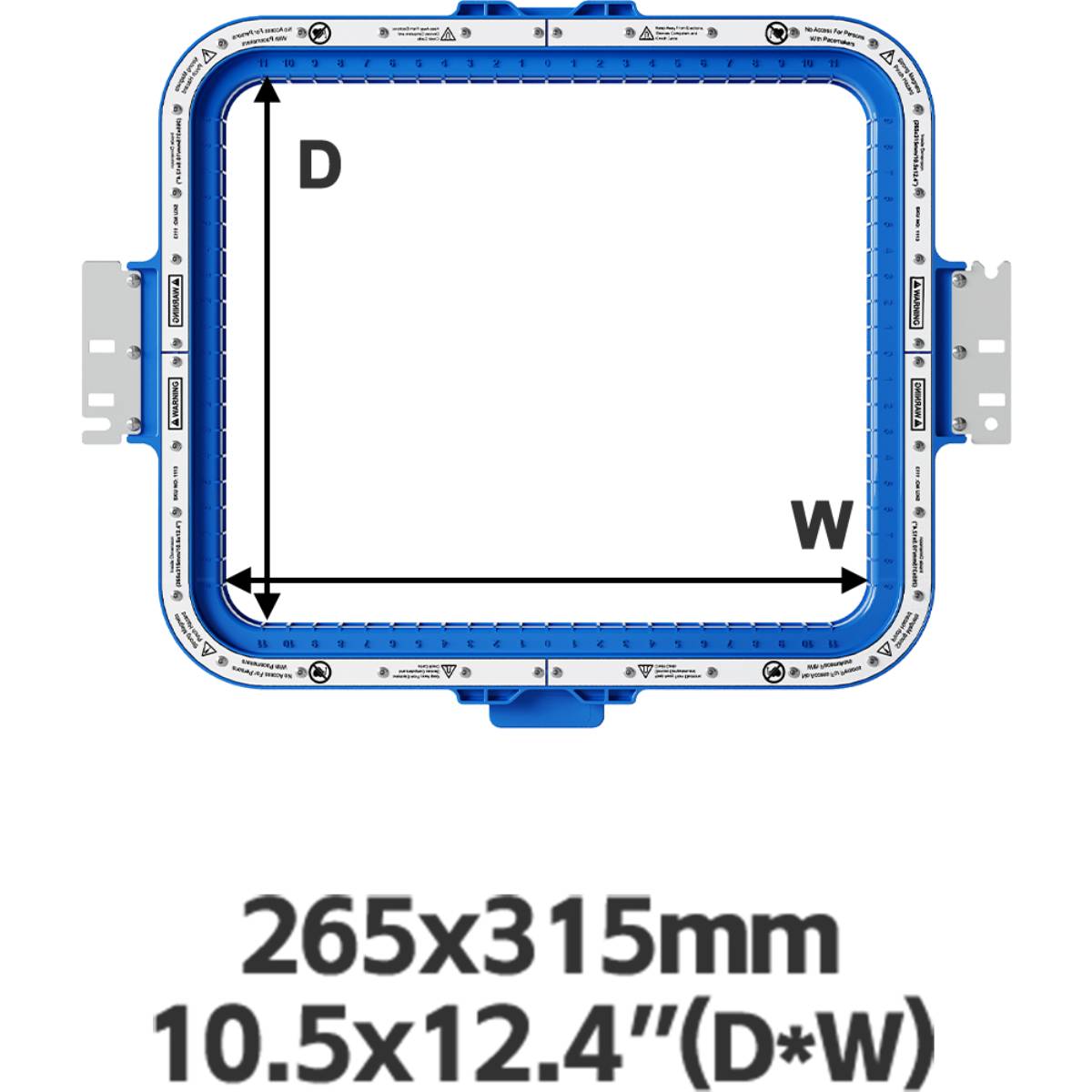

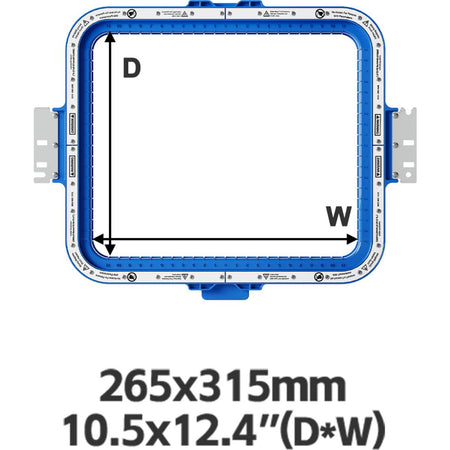

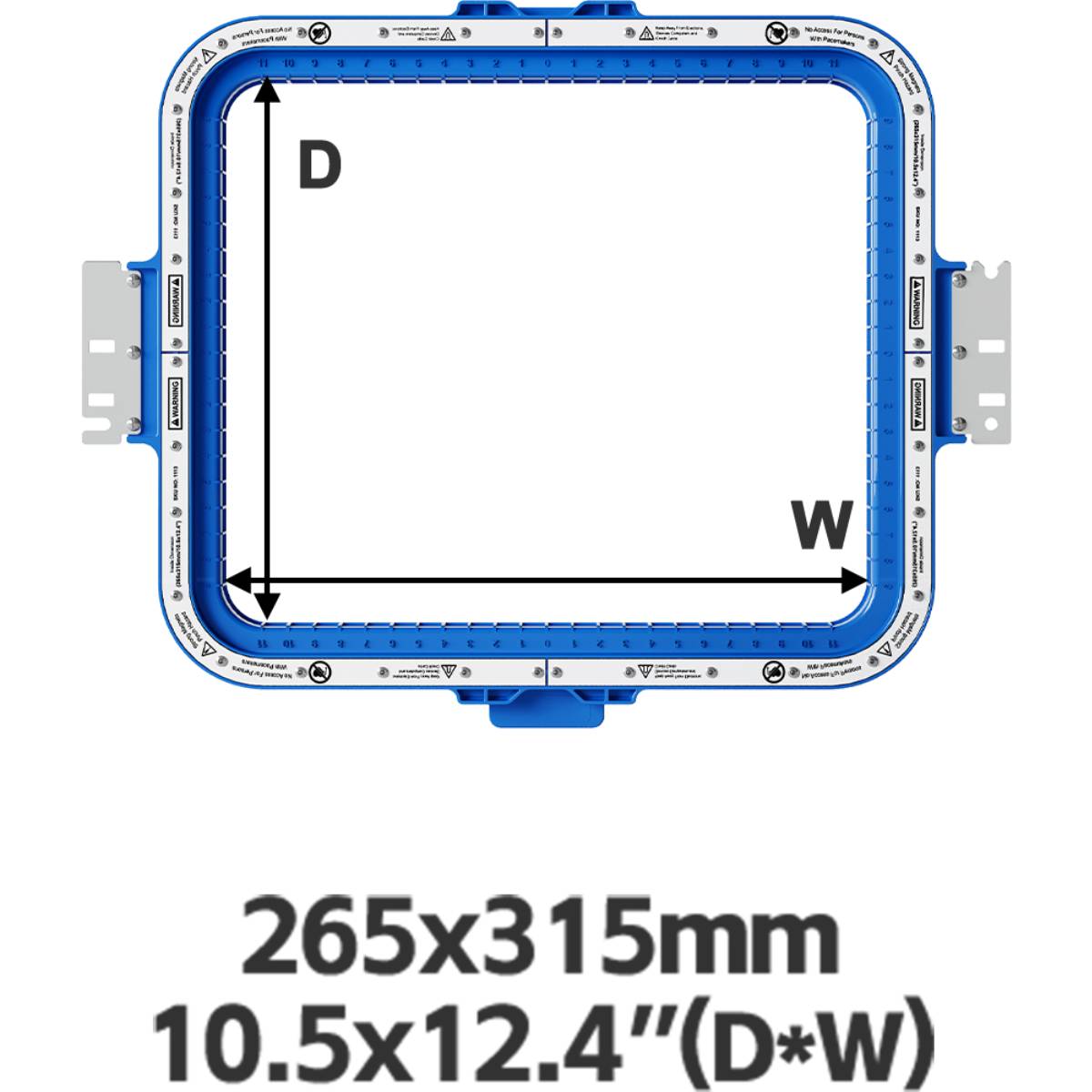

10.5″x12.4″(265x315mm) refers to the inner hoop dimension. The actual sewing field is about 9.7″x11.6″(245x295mm).

Product Features

Super durable and strong embroidery magnetic hoop: tested with 500,000 repeated uses and strict destructive testing to ensure long-lasting magnetic hoops embroidery performance.

Ideal for all kinds of fabric hooping: this magnet hoop easily secures heavy, thin, fragile, stretchy, and elastic fabrics, making embroidery hoop setup simple and precise.

Available in 17+ frame sizes ranging from 3.9x3.9 inch/100x100mm to 17x15.5 inch/430x390mm, these embroidery magnetic hoops meet a variety of embroidery project needs.

Tough Durability Testing Video

Watch video

Product Application

It is perfect for magnetic hoop embroidery on large square or rectangular patterns on sweatshirts, jackets, T-shirts, jeans, and polo shirts.

Excellent for pillows, home décor, tablecloths, blankets, large bags, and embroidery patches, these magnet hoops make fabric framing quick and stable.

Customer Using Reference

Watch video

Packing List

1. Hoop Main Part x 1 pcs

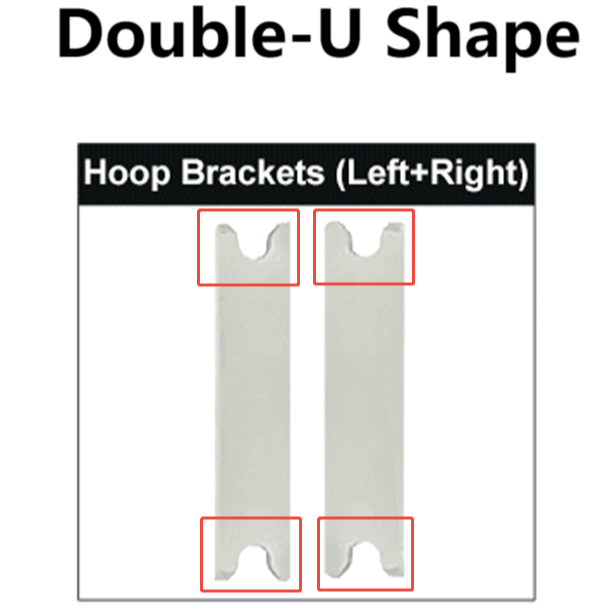

2. Metal Brackets x 1 pair

3. Screws & Screwdriver

(Note: Brackets will be matched according to your machine brand, and need to be assembled on hoop main part with screws)

Compatible with KIMDOOSKY Embroidery Machine Models.

KIMDOOSKY single head machine models:

- KD-CT1201S / KD-CT1501S / KD-CT1201 / KD-CT1501

KIMDOOSKY multi-heads machine models:

- 2 Heads : KD-CT1202H / KD-CT1502H

- 3 Heads : KD-CT1203H / KD-CT1503H

- 4 Heads : KD-CT1204H/ KD-ECT904 /KD-ECT1204

- 6 Heads : KD-ECT906 / KD-ECT1206

- 8 Heads : KD-ECT908 / KD-ECT1208

- 10 Heads : KD-ECT910 / KD-ECT1210

- 12 Heads : KD-ECT912 / KD-ECT1212

We have a lot of different size hoops to compatible with KIMDOOSKY Embroidery Machines. Click Here to check all products for KIMDOOSKY embroidery machines.

For more product options, browse our full

Embroidery Hoops and Other Products collection

.

More Customer Share

---From a Mexico customer

Compatibility—Sewtalent large 12.4x15.6" magnetic hoop fits my Ricoma TC machine perfectly.

Watch video

---From a United States customer

Sewtalent magnetic hoop matches Mighty Hoop in quality at a better price.

Watch video

---From a Romania customer

How to use the hoop station and its benefits.

Watch video

---From a Korea customer

How to embroider using a hoop station with different sizes of magnetic hoops.

Watch video

FAQs

If I hoop the fabric crooked by mistake, is it easy to reposition? Will it damage the fabric?

Yes, it's incredibly easy! The Sewtalent magnetic hoop for KIMDOOSKY embroidery machines allows you to simply pop off the top frame, reposition your fabric, and snap it back in place within seconds. The smooth magnetic grip ensures there are no hoop marks or fabric damage, even when adjusting multiple times during setup.

When using this magnetic frame, should the stabilizer be placed inside the frame or 'floated' outside of it?

Both methods work well. For most embroidery projects on KIMDOOSKY machines, sandwiching the stabilizer with the fabric inside the magnetic hoops gives the best stability. However, for thick, rigid, or delicate items, many embroiderers prefer the 'floating' technique by laying the stabilizer only under the bottom frame surface.

Are the top and bottom parts of the magnetic frame symmetrical, or do they have a specific orientation?

The Sewtalent embroidery magnetic hoop is designed with unique alignment. The top and bottom frames are shaped to fit perfectly with matched magnets, ensuring precise registration every time you hoop. This structure minimizes shifting and guarantees consistent results across all KIMDOOSKY models, including KD-CT1201 and KD-ECT906.

What productivity gains can I expect when using these magnetic hoops on multi-head KIMDOOSKY machines?

Switching your multi-head KIMDOOSKY embroidery setup to Sewtalent magnetic hoops can save 30–60 seconds per hooping per head. Over an 8-hour production shift, this adds up to a 15–25% increase in throughput. The secure magnet grip and easy release mechanism streamline fabric loading, reducing downtime and increasing output efficiency dramatically.