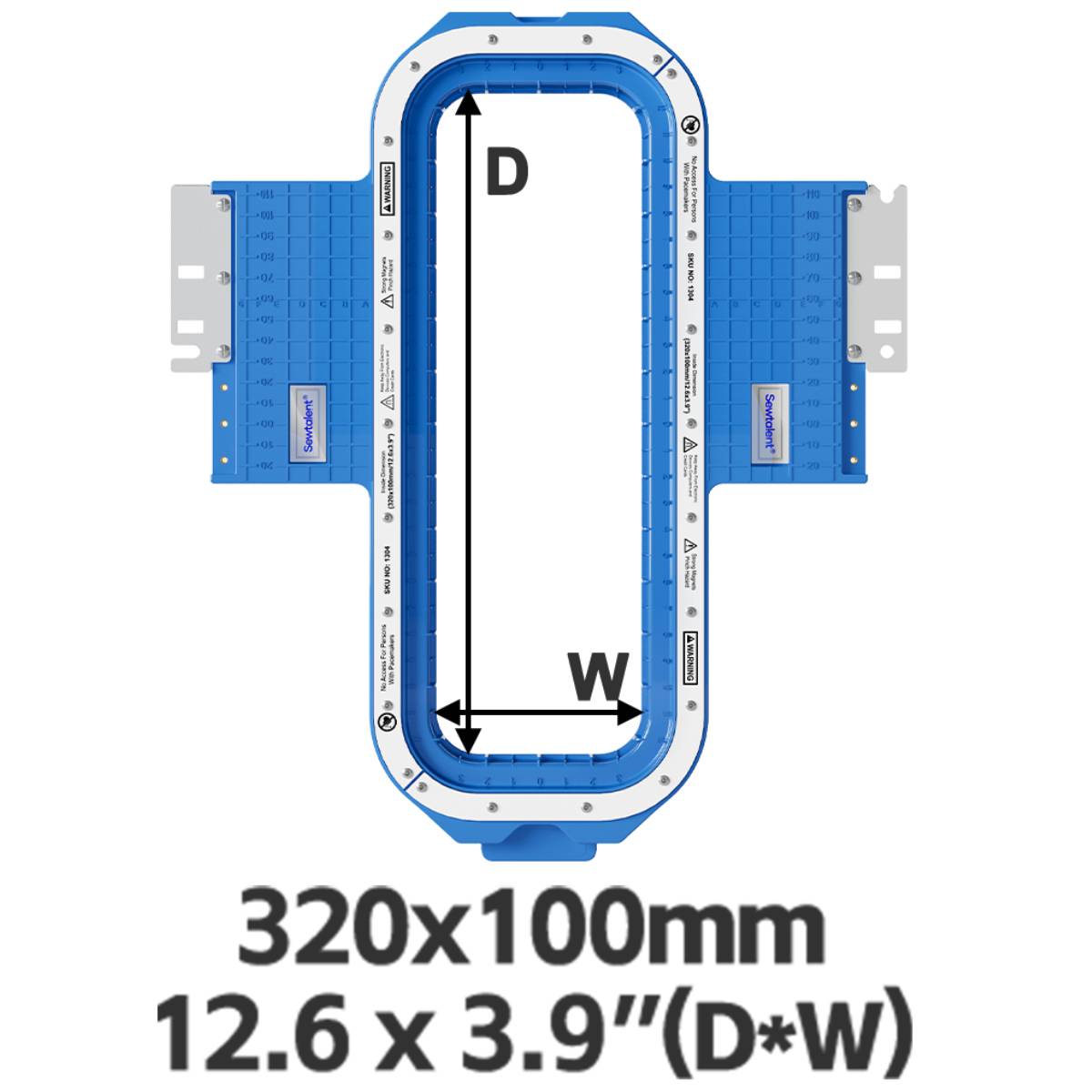

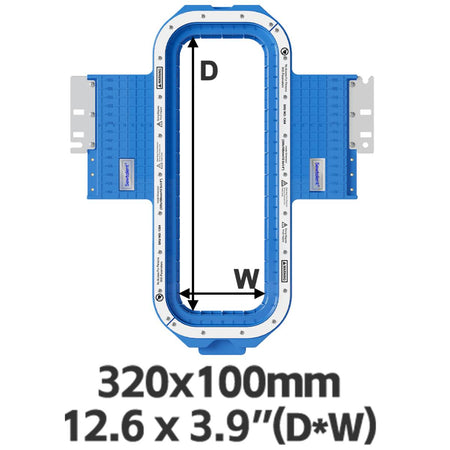

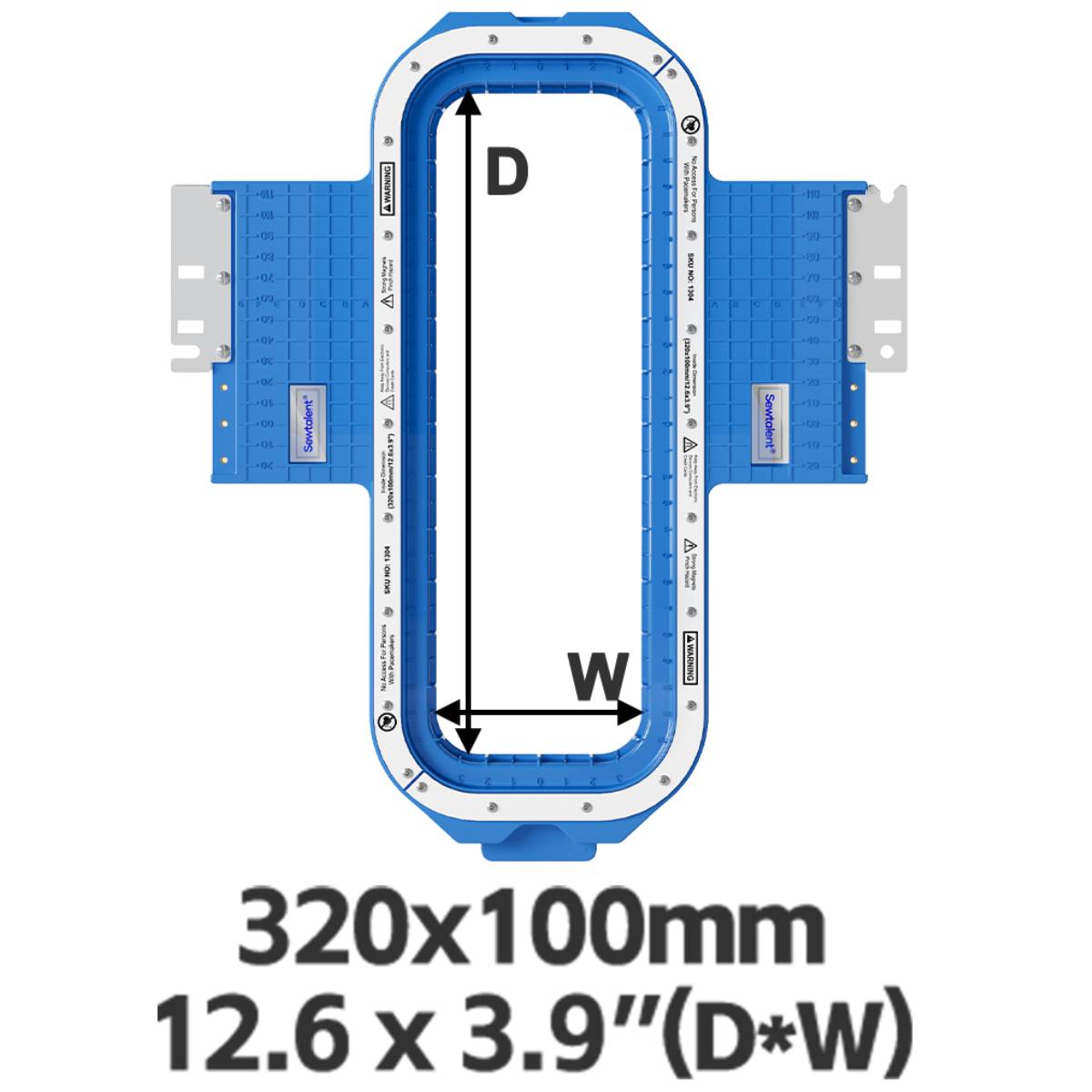

12.6″x3.9″(320x100mm) refers to the inner hoop dimension. The actual sewing field is about 11.8″x3.1″(300x80mm).

Product Features

Super durable and strong, this magnetic hoop embroidery frame is tested over 500,000 times for repeated use and strict destructive testing to ensure lasting performance.

Ideal for all kinds of fabric hooping with machine embroidery hoops, especially for hard-to-clamp items like heavy, thin, fragile, stretchy, and elastic fabrics.

With 17+ hoop sizes ranging from 3.9x3.9 inch/100x100mm to 17x15.5 inch/430x390mm, these magnetic frames meet diverse embroidery needs from small patches to large patterns.

Tough Durability Testing Video

Watch video

Product Application

It is perfectly embroidering long patterns on sleeves, trouser legs, children’s clothing, and bags like backpacks or canvas bags, making it a versatile magic hoop option for creative embroidery projects.

Customer Using Reference

Watch video

Packing List

1. Hoop Main Part x 1 pcs

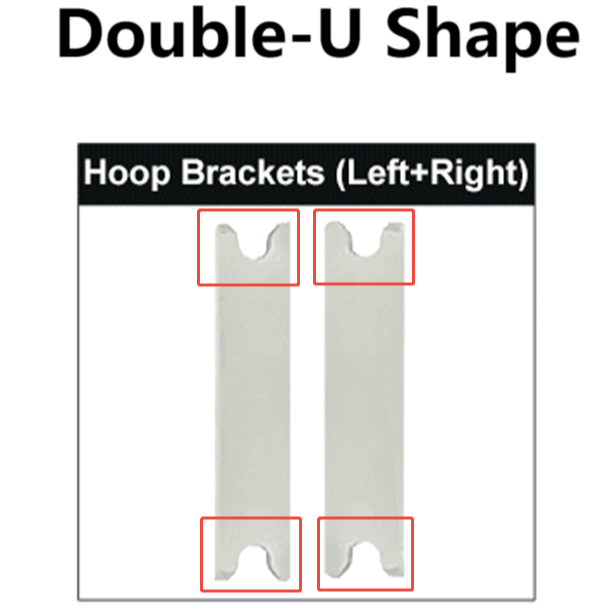

2. Metal Brackets x 1 pair

3. Screws & Screwdriver

(Note: Brackets will be matched according to your machine brand, and need to be assembled on hoop main part with screws)

Compatible with Kingstar embroidery machine models, this magnetic frame offers stable performance across various machines for professional magnetic hoops embroidery.

Kingstar single head machine models:

- kingstar KSQ901/ kingstar KSQ1201/ kingstar KSQ1501

- kingstar KSQ901L/ kingstar KSQ1201L/ kingstar KSQ1501L

- kingstar KSQ901ML/ kingstar KSQ1201ML/ kingstar KSQ1501ML

- kingstar Kingstar BF-1200/ kingstar Kingstar 1201/ kingstar Kingstar 1201R

- kingstar Sevmak 1201CT/ kingstar Sevmak 1201CTM

Kingstar multi-heads machine models:

- 2 Heads: Kingstar 1202

- 4 Heads: Kingstar 1204

We have a lot of different size hoops to compatible with Kingstar Embroidery Machines. Click Here to check all products for Kingstar embroidery machines.

For more product options, browse our full

Embroidery Hoops and Other Products collection

.

More Customer Share

---From a Romania customer

Sewtalent Magnetic Hoop Durability Test—Outstanding Quality.

Watch video

---From a France customer

Using the Sewtalent hoop station and magnetic hoop on a Holiauma machine—100% recommended.

Watch video

---From a United States customer

Real user feedback—highly recommends Sewtalent; great value for money.

Watch video

---From a Korea customer

How to embroider using a hoop station with different sizes of magnetic hoops.

Watch video

FAQs

If I switch all the stations on my multi-head machine to these magnetic frames, what is the potential increase in daily throughput?

The efficiency gain with Sewtalent magnetic hoops for Kingstar embroidery machines scales quickly on multi-head models such as Kingstar 1202 and 1204. By saving 30–60 seconds per hooping per head, an 8-hour shift can deliver 15–25% higher total output. This also minimizes operator fatigue and ensures consistent hooping tension on every station.

Who should I contact for technical support if I have trouble with installation or use?

Our expert support team is always ready to help with Kingstar machine compatibility, installation, or tension adjustment. You can reach us through email, phone, or live chat on our website for prompt technical assistance and setup guidance to ensure your Sewtalent magnetic hoop performs optimally from the start.

For a new employee, which has a shorter learning curve: training them on this magnetic frame or on a traditional screw hoop?

The magnetic frame for Kingstar embroidery machines has a much shorter learning curve than a traditional screw hoop. Its snap-and-lock design simplifies fabric alignment and tension control, allowing new operators to achieve accurate hooping immediately. This reduces training time and minimizes wasted fabric due to incorrect setup.

How does switching to this magnetic hoop reduce defect rates or fabric damage?

Using Sewtalent magnetic hoops for Kingstar models like KSQ901 and KSQ1501 helps prevent hoop burn and fabric puckering. The even magnetic pressure keeps materials stable, significantly lowering defect rates caused by uneven tension. Over time, shops report reduced waste and higher-quality embroidery finishes, improving production cost efficiency.