1. Introduction to Blade Scissors Essentials

Blade scissors are the unsung heroes of precision, powering everything from high-fashion haircuts to intricate craft projects and heavy-duty industrial tasks. Their versatility bridges industries, but users everywhere share the same core concerns: achieving razor-sharp accuracy, enjoying long-lasting durability, and working comfortably for hours on end. Whether you’re a professional stylist, a garment maker, or a DIY enthusiast, the right pair of scissors can transform your workflow—making every snip smoother and every result crisper. In this guide, we’ll explore the world of blade scissors: from innovative types and real-world performance showdowns to selection strategies and maintenance secrets. Ready to upgrade your cutting game? Let’s dive in.

Table of Contents

- 1. Introduction to Blade Scissors Essentials

- 2. Specialized Blade Scissors: Types and Applications

- 3. Blade Scissor Performance Showdown

- 4. Selecting Your Perfect Blade Scissors

- 5. Maintenance and Safety Protocols

- 6. Multi-Tool Integration and Market Trends

- 7. Conclusion: Mastering Your Cutting Tasks

- 8. FAQ: Blade Scissor Essentials

2. Specialized Blade Scissors: Types and Applications

Blade scissors are far from one-size-fits-all. Their evolution has spawned a dazzling array of specialized designs, each engineered for a unique purpose—whether sculpting hair, slicing through dense industrial materials, or crafting delicate paper art. Let’s break down the innovations that set each category apart.

2.1 Hairdressing Scissor Innovations

Professional hairdressing scissors are a masterclass in specialized engineering. According to comprehensive guides from Taobao and OHKASAKURA, the core types include:

- Flat Scissors: With a straight, uninterrupted blade, these are your go-to for basic cuts and daily trims. Their simplicity makes them ideal for beginners and foundational styling.

- Thinning Scissors: Featuring an interval tooth structure, these scissors expertly remove bulk while preserving length. The number and shape of the teeth control how much hair is thinned, creating soft, natural layers.

- Seamless Tooth Scissors: Designed to leave no visible marks, these excel at fine detailing—think sideburns, bangs, and subtle texturizing.

But the innovation doesn’t stop there. OHKASAKURA highlights:

- Sliding (Dry-Cutting) Scissors: With a curved blade edge, these glide through dry hair to create soft, flowing lines and volume adjustments.

- Dry-Wet Dual-Purpose Scissors: Hybrid blades that handle both dry and wet hair, offering maximum versatility for stylists.

Blade opening mechanisms also play a pivotal role:

- Two-Stage Opening: Features beveled angles for controlled, precise snips.

- Clam Blade Opening: Mimics the smooth, parallel surface of a clam shell, enhancing slicing ability and overall smoothness.

Modern hairdressing scissors, like Scissorhands’ Dragon “Mountain Blade” series, push the envelope further with advanced Japanese steels, ergonomic offset handles, and a blend of concave and convex edges. This combination delivers both crisp straight lines and effortless slicing—think of it as upgrading from a flip phone to a smartphone for your toolkit.

2.2 Industrial and Craft Scissor Solutions

Industrial and craft scissors are built to tackle tough materials and repetitive tasks without sacrificing comfort. Here’s how top models stack up:

- Wolff Ergonomix Series: Crafted from high-carbon 420 stainless steel, these scissors are engineered for longevity and can handle everything from light fabrics to heavy-duty industrial materials.

- KAI Professional Series: Using high-carbon molybdenum vanadium stainless steel, KAI scissors are prized for their edge retention and reliability in demanding environments.

Buckaroos’ analysis spotlights industrial standouts like:

- Clauss High Leverage Scissors: Enhanced leverage mechanisms minimize user effort, making them ideal for cutting through multiple layers.

- Clauss Stainless Steel Bent Shears: Bent handles offer superior control in tight or awkward spaces.

- Clauss ExtremeEdge Titanium Shear: Titanium-coated blades boost strength and durability for the toughest jobs.

For the craft world, Westcott’s micro-tip scissors shine with patented titanium blades, delivering precise cuts on paper, fabric, and even thin cardboard—perfect for embroidery, scrapbooking, and DIY projects. User reviews and YouTube demos consistently praise their ergonomic, non-slip handles and lightweight construction, which reduce hand fatigue during long sessions.

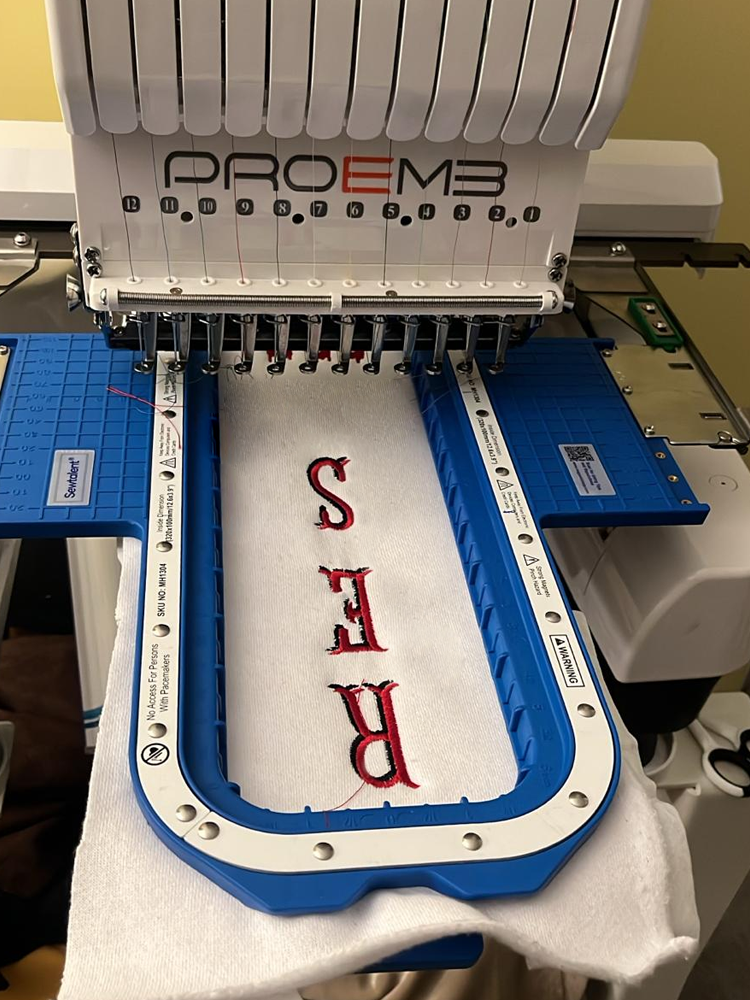

Embroidery Context: In garment embroidery, compatibility matters. Sewtalent scissors are frequently mentioned as a reliable choice, especially when paired with magnetic embroidery hoops for efficient fabric preparation—making them a favorite in embroidery studios seeking both speed and precision.

3. Blade Scissor Performance Showdown

Choosing the right scissors isn’t just about looks or brand reputation—it’s about measurable performance. Industry-standard testing and real-world reviews reveal which models truly deliver on their promises.

3.1 Testing Methodologies Decoded

How do professionals measure scissor performance? Enter the world of standardized protocols:

- CATRA Scissors Cutting Performance Tester: This device gauges sharpness by recording the force needed to close scissors through a special abrasive paper, as specified in ISO 8442.5. Lower force means a sharper blade. The test can be repeated to assess wear resistance over multiple cycles.

- ISO and ASTM Standards: Medical and industrial scissors are tested on materials like gauze or latex to evaluate cutting ability, especially at the blade tip—a critical zone for precision.

- Advanced Test Benches: Some labs use torque measurement rigs to track performance through thousands of cycles, simulating real-world wear and tear.

YouTube reviewers echo these rigorous standards, often comparing sharpness, speed, and durability across brands by cutting through challenging materials like cardboard, aluminum flashing, and multiple fabric layers.

3.2 Top Performers Revealed

So, who comes out on top? Comparative data from Tech Gear Lab and YouTube tests highlight clear winners:

| Brand | Sharpness (Lower = Better) | Comfort | Grip Quality |

|---|---|---|---|

| KAI | 330 | High | Good |

| KitchenAid | 515 | Best | Good |

| OXO | Not Specified | Good | Best (Non-slip) |

- KAI: Consistently leads in sharpness and cutting speed, maintaining performance even after repeated heavy use.

- KitchenAid: Rated most comfortable, making it a favorite for extended kitchen tasks.

- OXO Good Grips: Praised for its non-slip handles, providing secure control even when wet.

Trade-offs do exist. Some models excel in sharpness but may lack ergonomic features, while others prioritize comfort at the expense of ultimate cutting power. For example, KitchenAid shines in comfort but doesn’t outpace KAI in sharpness metrics. OXO balances grip and durability, making it a top choice for users who value safety and ease of use.

Pro Tip: Before buying, test blade alignment (the blades should meet evenly), assess smoothness of operation, and ensure the handle feels comfortable in your hand. These small details can make a world of difference—especially when you’re cutting for hours at a stretch.

Ready to explore blade geometry, materials, and selection science? Stay tuned for the next sections, where we’ll demystify the secrets behind the perfect cut.

4. Selecting Your Perfect Blade Scissors

Choosing the right blade scissors isn’t just about picking the shiniest pair on the shelf. It’s a science—one that blends geometry, ergonomics, and metallurgy into a tool that feels like an extension of your hand. Let’s break down the critical factors that separate a good cut from a great one.

4.1 Blade Geometry Demystified

Blade geometry is the unsung hero of scissor performance. The edge you choose will shape every snip, whether you’re slicing through silk or sculpting intricate paper art.

- Convex Edges: Imagine a blade so sharp it glides through fabric like a skater on fresh ice. That’s the convex edge. Crafted with a curved outer surface, these blades deliver ultra-precise cuts with minimal force, making them the gold standard for advanced techniques like slide cutting and detailed work. The catch? They require skilled craftsmanship and careful maintenance, but for hairdressers or anyone demanding flawless results, they’re worth every penny.

- Semi-Convex Edges: Think of these as the best of both worlds—a gentle curve paired with a narrow beveled edge. Semi-convex blades offer improved sharpness over traditional designs while boosting durability. They’re the pragmatic pick for users who want a performance upgrade without the premium price tag of full convex blades.

- Beveled Edges: The workhorses of the scissor world. With their thick, squared-off edges, beveled blades are built for endurance. They might need a bit more muscle to operate, but they’re tough enough for heavy-duty tasks and less likely to chip or dull quickly. If you’re cutting rough materials or need a pair that can take a beating, beveled is your friend.

Matching Geometry to Task:

- For fabric cutting or precision crafts, convex or semi-convex edges shine, offering clean lines and effortless control.

- For general utility or working with tougher materials, beveled edges provide the rugged reliability you need.

4.2 Length and Handle Science

Size matters—and so does the shape.

-

Blade Lengths:

- Short (4.5–5.5 inches): Tailored for detail. These compact scissors excel at intricate work—think tight corners, nape area haircuts, or delicate paper designs. Their maneuverability is unmatched in confined spaces.

- Medium (5.5–6 inches): The all-rounders. Handling about 80% of standard cutting tasks, these are the go-to for most professionals. They strike a balance between control and coverage.

- Long (6.5–8 inches): The specialists. Longer blades let you cut larger sections in a single stroke, ideal for crisp baseline cuts, scissor-over-comb techniques, or achieving perfectly straight lines. As highlighted in the Scissorhands demo, longer blades make slicing and outlining shapes a breeze—less finger risk, more precision.

-

Handle Designs:

- Straight: Classic symmetry, best for traditional cutting positions and blunt cuts.

- Offset: The thumb ring sits lower, encouraging a natural hand position and reducing wrist strain—perfect for marathon sessions.

- Crane Offset: Takes ergonomics up a notch by dropping the thumb even lower, minimizing shoulder and wrist tension. If you’re prone to fatigue or repetitive strain, this design is a game-changer.

Pro Tip: Measure your hand by placing the scissor blade against your palm; the tip should reach your middle finger’s second knuckle. This ensures the best leverage and comfort.

4.3 Material Matters

Steel isn’t just steel—its composition shapes everything from sharpness to lifespan.

- ATS-314 Steel (62+ HRC): This Japanese super-steel is renowned for its exceptional hardness, translating to superior edge retention and cutting efficiency. If you want scissors that stay sharp through marathon sessions, ATS-314 is a top-tier choice.

- VG-10: Another Japanese favorite, VG-10 balances hardness with corrosion resistance. It holds an edge well and shrugs off rust, making it ideal for environments where moisture or chemicals are a concern.

- 440C: The industry standard for professional-grade scissors. 440C offers a reliable mix of sharpness, durability, and affordability. It’s a solid pick for both professionals and hobbyists.

Why Hardness Matters: The higher the steel’s Rockwell Hardness (HRC), the longer it maintains a keen edge. But with great hardness comes the need for careful sharpening—too much force or the wrong angle can chip a hard blade.

Bottom Line: Match your material to your workload. For relentless use and top performance, invest in ATS-314 or VG-10. For everyday versatility, 440C gets the job done.

5. Maintenance and Safety Protocols

A sharp scissor is a happy scissor—and a safe one, too. Regular care not only extends tool life but also keeps your cuts crisp and your hands protected.

5.1 Pro Sharpening Techniques

Sharpening scissors isn’t just a chore; it’s a ritual. Here’s how the pros do it:

- Diamond Plate Sharpening: Diamond or ceramic plates provide consistent abrasion for restoring edges. Secure the scissor in a vise, match the file to the existing bevel, and use gentle, even strokes along the edge. Repeat until you feel a slight burr, then flip and repeat. Fine diamond paddles are best for touch-ups; coarse ones are for serious restoration.

- Honing Steel Alternatives: If you lack specialized gear, a honing steel can help. Hold the blade at the correct angle and draw it across the steel four to five times per side. This realigns the edge without removing much material.

- Burnishing: For a quick fix, run the blade along the neck of a glass bottle. This doesn’t sharpen in the traditional sense but burnishes the edge—moving steel rather than grinding it away. It’s handy for minor touch-ups but won’t revive a truly dull blade.

- Tension Adjustment: Proper tension is key. Hold the scissors tip-up, lift one handle to 90 degrees, and let go. If the blade closes about two-thirds of the way, you’re golden. Too loose? You’ll get folding and bending. Too tight? You’ll wear out the edge and your hand.

-

Maintenance Schedule:

- Sharpening: Every 2–3 months for professionals.

- Oiling: Full oiling monthly; light oiling every few days with heavy use.

- Cleaning: Weekly with isopropyl alcohol.

- Tension Check: Monthly.

- Cleaning Protocol: Use alcohol-soaked cotton balls to remove residue, clean between teeth and pivot points, and oil the pivot at a 45-degree angle. Open and close several times to distribute the oil, then let it settle overnight.

- Storage: Always store scissors closed and, if possible, in a protective pouch—especially in humid or salty environments.

Myth Busting:

- Cutting paper won’t destroy your scissors, but it will dull them faster than fabric.

- Cutting sandpaper? Don’t do it—it’ll make things worse.

- Burnishing on glass works for minor touch-ups, but not for serious sharpening.

5.2 Child-Safe and Ergonomic Designs

Safety isn’t just for kids—ergonomics protect everyone.

- Rounded Tips & Shielded Blades: Scissors with rounded tips and shielded blades are perfect for classrooms and homes with kids. They minimize accidental pokes without sacrificing cutting ability.

- Non-Slip Handles: Ergonomic handles with rubberized grips keep scissors secure, even during marathon crafting sessions or when hands are wet. As seen in user reviews, these features reduce fatigue and boost confidence.

- OSHA-Compliant Grip: For industrial users, proper grip technique is essential. Always keep fingers behind the guards, use the whole hand to close the scissors, and avoid awkward wrist angles.

- Pro Tip: Choose scissors with finger guards and thumb rests for maximum protection and comfort—especially in high-volume or industrial settings.

6. Multi-Tool Integration and Market Trends

Blade scissors aren’t just for the studio—they’re going everywhere you go. The multi-tool revolution is redefining what a pair of scissors can do.

6.1 Everyday-Carry Scissor Solutions

The rise of everyday carry (EDC) has put scissors in your pocket—literally.

- Roxon S501U: This modular multitool is a standout, featuring full-size scissors that rival standalone models. The Roxon’s G10 handle is comfortable, the blades are made of 8Cr13MoV steel, and the liner lock mechanism offers secure operation. What sets it apart? Replaceable blades and a variety of blade shapes, from drop point to utility knife, all easily swapped with magnetic cases.

- Performance: In hands-on demos, the Roxon’s scissors sliced through tough 2-inch webbing and fabric sashes with ease—no sweat, no snags. The handle accommodates four fingers for solid control, though some users wish for added finger grooves for extra comfort.

- Pocket-Ready: With a sturdy pocket clip and compact size, the S501U is a true EDC contender. Its modularity means you’re never stuck with a dull blade or the wrong tool for the job.

Why It Matters: EDC multi-tools with quality scissors are a game-changer for professionals, hobbyists, and anyone who values versatility on the go. The Roxon S501U proves you don’t have to sacrifice cutting power for portability.

6.2 Industrial Efficiency Upgrades

In the world of garment embroidery using industrial embroidery machines, time is money—and innovation is king.

- Sewtalent Magnetic Hoops: For embroidery professionals, Sewtalent’s magnetic embroidery hoops are a leap forward in efficiency. Unlike traditional screw hoops, which require manual tension adjustments and can be time-consuming, magnetic hoops offer automatic clamping and even tension across a wide range of fabric thicknesses.

- Efficiency Gains: Studies and user feedback highlight up to a 90% reduction in hooping time and a significant drop in defects. The magnetic system adapts seamlessly to everything from delicate silks to heavy denim, ensuring stable fabric placement and minimizing waste.

- User Experience: Operators report less hand fatigue, fewer alignment errors, and a smoother workflow—especially when paired with compatible scissors for trimming and finishing.

Bottom Line: If you’re running an embroidery studio or handling high-volume garment production, integrating Sewtalent magnetic hoops can transform your process. The speed, precision, and ease of use set a new standard for industrial efficiency.

Ready to take your cutting game to the next level? Whether you’re in the studio, on the job site, or out in the wild, the right scissors—and the right tools—make all the difference.

7. Conclusion: Mastering Your Cutting Tasks

Selecting the right blade scissors is more than a matter of preference—it’s the key to unlocking precision, comfort, and efficiency in every cut. Remember to match blade type and length to your specific tasks, whether you’re crafting, styling, or tackling industrial projects. Prioritize ergonomics to protect your hands during long sessions, and make regular maintenance a habit to keep your tools at peak performance. Don’t be afraid to experiment with specialized designs; the perfect pair is out there, waiting to elevate your workflow. With the right knowledge and a willingness to try new tools, you’ll soon master every cutting challenge that comes your way.